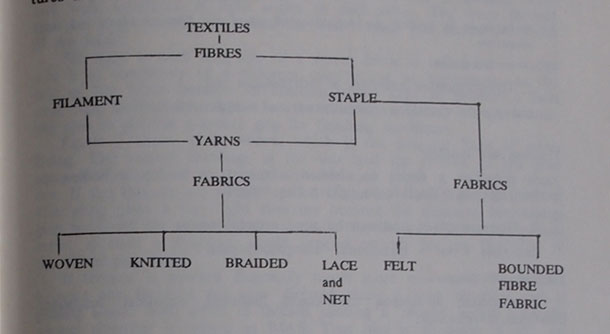

It is generally accepted that a textile is a fabric made from fibres. (Принято считать, что текстильное изделие – это ткань, сделанная из волокна.) But Figure 1 shows that the fibres may either be converted into yarn first and then the yarns put together to make fibres, or the fibres can be converted directly into a fabric. (Но на Рисунке 1 видно, что волокно может быть преобразовано сначала в пряжу, а потом из этой пряжи делают ткани, либо волокно может быть сразу преобразовано в ткань.)

Figure 1 (Рис.1.)

- Textiles – текстильные изделия.

- Fibres – волокно.

- Filament – текстильная нить.

- Staple – элементарное (текстильное) волокно.

- Yarn – пряжа.

- Fabrics – ткань.

- Woven (fabric) – тканое изделие.

- Knitted (fabric) – вязаное, трикотажное изделие.

- Braided (fabric) – плетёная ткань.

- Lace (fabric) – кружевная ткань.

- Net (fabric) – тюль.

- Felt (fabric) – нетканый материал, валяное изделие, войлок.

- Bonded fibre fabric – клееное нетканое полотно.

But not all fibres are suitable for textile purposes because a textile fibre must possess sufficient length, fineness, strength and flexibility to be suitable for manufacture into fabrics. (Не все волокна подходят для текстильных изделий, так как текстильное волокно должно иметь достаточную длину, высокое качество, прочность и эластичность, чтобы быть подходящим для изготовления тканей.)

The basic structural elements of all textiles (woven fabrics, knitted and bonded fabrics, braids, laces) are staples and filaments. (Основными структурными элементами всех текстильных материалов (тканей, трикотажных и нетканых полотен, тесьм, кружев) являются текстильные (элементарные) волокна и текстильные нити.) These two terms – staple and filament – represent the two basic forms of textile fibres. (Эти два термина – текстильное (элементарное) волокно и текстильная нить – являются двумя основными формами текстильных волокон.)

Staple is the name given to fibres of limited length used for manufacturing of yarn and textile products. (Текстильное волокно – это волокно ограниченной длины, употребляемое для изготовления пряжи и текстильных изделий.) An example of a natural staple fibre is cotton. (Пример натурального текстильного волокна – хлопок.)

Filament is the name given to a fibre of continuous length. (Текстильная нить – это нить ограниченной длины.) An example of a natural filament is silk. (Пример натуральной текстильной нити – шелк.)

All fibres fall into (Все волокна подразделяются на):

- natural – obtained from natural sources, such as wool from sheep (натуральные – полученные из натуральных источников, например, шерсть овец);

- chemical – produced from various substances by chemical processes (химические – произведенные из различных веществ при помощи химических процессов).

After cleaning and blending, the fibres are spun into yarn. (После чистки и смешивания волокна скручивают в пряжу.) Yarn can consist of either staple fibres, or of filaments put together. (Пряжа может состоять либо из текстильных волокон, либо из текстильных нитей, соединенных вместе.) This is then processed into fabric in a weaving mill or knitting mill. (Далее она преобразовывается в ткань на ткацкой или трикотажной фабрике.) The next stage, called finishing, includes various mechanical and chemical processes for (Следующая стадия, называемая отделкой, включает различные механические и химические процессы для):

- Removal of defects or foreign matter (удаления дефектов или сорных примесей).

- Bleaching (отбеливание).

- Removal of moisture (удаление влажности).

- Dyeing (окрашивание).

- Printing (набивка).

The appearance of the fabric may also be improved by napping, shearing, pressing, brushing, and polishing. (Внешний вид ткани может также улучшаться ворсованием, стрижкой ткани, прессованием, очисткой и шлифовкой.)

After finishing, the woven material is ready for delivery to (После отделки тканый материал готов к доставке):

- A manufacturer of textile products such as clothing, household linens and bedding, upholstery, rugs and carpets. (Производителю текстильной продукции, такой как одежда, льняные ткани и штучные изделия домашнего обихода, постельные принадлежности, обивочный материал, ковровые покрытия и ковры.)

- A retailer, who sells it to individuals to make clothes or household articles such as curtains. (Розничному торговцу, который продает его людям для пошива одежды или предметов домашнего обихода, например, штор.)

Various techniques and processes are used to produce fibres of different qualities (Для производства волокон разного качества используются различные методы и процессы):

Fibres

- Acetate (ацетатная ткань).

- Cotton (хлопок).

- Linen (льняная ткань).

- Nylon (нейлон).

- Polyester (полиэстер).

- Rayon (вискоза, искусственное волокно).

- Silk (шелк).

- Wool (шерсть).

Techniques and processes

- Blending (смешивание).

- Braiding (плетение).

- Carding (прочёсывание, ворсование).

- Embroidering (вышивание).

- Fibre processing (обработка волокна).

- Knitting (вязание).

- Lace-making (кружевоплетение; производство кружев).

- Net-making (сетевязание).

- Spinning (прядение).

- Weaving (процесс ткачества).

Qualities of fibres

- Ability to withstand laundering or dry-cleaning (способность выдерживать стирку или химчистку).

- Absorption (впитывание).

- Crease control (контроль складок).

- Elasticity (эластичность).

- Fineness (высокое качество).

- Flexibility (гибкость, упругость).

- Length (длина).

- Reaction to heat and light (реакция на жару и свет).

- Shrinking control (контроль сжатия).

- Strength (сопротивление деформации).

- Wash and wear (не требующий глажки после стирки).

Looking after your fabrics is important if you want to make them last. Care labels tell you about (Если хотите, чтобы ткань прослужила долго, за ней необходимо следить. Ярлыки на одежде расскажут вам следующее):

| Washing (стирка) |  |

Indicates that normal (maximum) washing conditions may be used at the appropriate temperature; the number indicates the maximum temperature (Максимальная температура стирки) |

| Bleaching (отбеливание) |  |

Means that chlorine bleach may be used (Разрешена стирка с отбеливателями, содержащими хлор) |

| Ironing (глажка) | Means that a hot iron may be used (Можно гладить) | |

| Dry-cleaning (химчистка) |  |

Indicates that the garment must be professionally cleaned (Указывает, что одежде необходима профессиональная чистка) |

| Tumble drying (сушка во вращающемся барабане) |  |

Means that the garment may be tumble dried (Можно сушить во вращающемся барабане) |

А теперь предлагаем выполнить следующие задания.

- Read the information above. Mark the following statements T (true) or F (false). Give reasons.

- A textile is a fabric always made from fibres.

- All fibres are suitable for textile purposes.

- Filament is a fibre of continuous length.

- Staple is a fibre of limited length.

- Fibres can be spun into yarn or made into fabrics.

- Classify the following fabrics into their fibre type – natural (N) or synthetic (S). Then choose from the box below which characteristics best describe each fabtic.

Fabric Fibre type Characteristics Cotton Linen Nylon Polyester Silk Wool a) Good insulator; luxurious, soft to the touch.

b) Good strength, twice as strong as cotton; crisp to the touch.

c) Lightweight; easy to wash; resists shrinkage and wrinkling.

d) Luxurious; thinnest of all natural fibres.

e) Soft to the touch; absorbent.

f) Strong; resistant to most chemicals. - Below are the instructions for how to look after your fabrics. Complete the texts using the words below.

* Dry-cleanable, * drying, * hand-washable, * machine-washable, * shrinkage, * stain, * stretching, * sunlight When caring for your fabrics, remember that:

COTTON

is easy to care for. It is (a) ______ and dry-cleanable and has good colour retention.LINEN

is twice as strong as cotton and hand-washable or (b) ______.SILK

is (c) _____ or dry-cleanable, but has poor resistance to prolonged exposure to (d) ______.NYLON

is easy to wash, resist (e) ______ and wrinkling, is fast (f) ______, but has poor resistance to continuous sunlight.POLYESTER

is resistant to (g) ______; can be washed or dry-cleaned; is quick drying and wrinkle resistant; because of its low absorbency, (h) ______ removal can be a problem.

Однако мы не упомянули еще один вид тканей – «интеллектуальные ткани» (intelligent fabrics). Предлагаем вашему вниманию видео на эту тему:

It’s the fashion show season, and in parallel, Paris has been hosting the largest textile show in the world – “Premiere Vision”. Seven hundred and forty-two exhibitors from thirty countries presented their offerings for the “Autumn – Winter 2007-2008” seasons. And this year some special guests – so-called intelligent fabrics – textiles, for example, that have built-in protection against staining.

- Intelligent fabrics – интеллектуальные ткани.

- Built-in protection against staining – «встроенная» защита от пятен.

If we imagine normal cloth being flat, with nanotechnologies the cloth takes a form a little like mountain. The structure’s invisible, of course, and dirt can’t stick to a material like that. It runs off. So, here I’ll put a bit of ketchup on and I’ll take some water and there you see it’s a white cloth, and you can rinse off the dirt immediately.

- Flat – ровный.

- Invisible – невидимый.

- Dirt can’t stick to a material – грязь не прилипает к материалу.

- To run off – стекать.

- To rinse off the dirt – смывать грязь

Stain resistant materials, bacteria resistant materials, mosquito resistant materials, materials that can absorb smell or reduce perspiration. Materials that can measure your heart beat, or your breathing pattern. Textiles that are totally impermeable, textiles that are ultra absorbent, cosmetic textiles that moisten the skin, or apply perfume.

- Stain resistant material – грязестойкий материал.

- Bacteria resistant material – антибактериальный материал.

- Mosquito resistant materials – антимоскитный материал.

- Absorb smell – поглощать запах.

- Reduce perspiration – сокращать потение.

- Impermeable – герметичный, непроницаемый.

- Moisten the skin – увлажнять кожу.

The world of intelligent textiles is expanding and a multitude of European research centres are part of it.

Here at Centexbel in Belgium, not far from Liege, scientists are dreaming of the next generation of intelligent or functional textiles. Prototype maker Martin Delgeder’s job is to transform these dreams into reality.

- Transform into reality – превратить в реальность.

Here we have a pullover that’s entirely knitted. The keyboard is supple. It enables the user to send a range of different commands. It was conceived for handicapped people, to allow them, for example, with a given code to open a garage door, to switch on the television. We’ve also got undergarments that allow you to monitor different body functions: breathing, heartbeat and so on using electrodes that are in direct contact with the body. We can also insert fibre optics into carpet. They are integrated in the production process to make the carpet luminous. They can be used for emergency exit, for example, if there’s a power-cut, or just to create putty patterns within the carpet. We’ve also used fibre optics in knitting. This creates the possibility of luminous knitwear. It can be used for outdoor safety clothing, or it can be stuck on walls and ceilings for decorative effects.

- Supple – мягкий, эластичный.

- It was conceived… – это было задумано…

- Handicapped people – люди с ограниченными возможностями.

- Undergarment – нижнее бельё.

- Fibre optics – волоконная оптика.

- Power-cut – прекращение подачи энергии.

- Putty – желтовато-серый.

- Luminous knitwear – светящаяся трикотажная одежда.

The most complex of these prototypes is probably the textile keyboard which can also function as a simple calculator. Jean Leonard has spent two years working on it. The key, and the interaction of materials that do and don’t conduct electricity.

In addition to the conventional materials, which are electrical insulators we’ve used metallic fibres that do conduct electricity. The principle is that when you don’t apply pressure, there is no contact between two conducting layers. And when you apply pressure, you create a contact between the two layers. In addition to this, there’s a small micro electric component which has been miniaturized as much as possible, so that it disrupts the cloth as little as possible, because the goal is to preserve the characteristics of the textiles: suppleness and comfort.

Suppleness and comfort – those are watchwords for functional and intelligent clothing. Yvette Rogister is in charge of the microbiology lab at the centre. She unlocks the secrets of textiles using this giant microscope. Her research helps to build an understanding how fibres react to the presence of certain nanoparticles. For example, cosmetic nanoparticles that release perfumes into clothes.

- Electrical insulators – электроизолятор.

- Conventional materials – материал на основе классических технологий.

- To disrupt – разрывать.

- Suppleness – эластичность.

There are microcapsules which contain a perfume that’s integrated within the fibres that make up the cloth. What we’ve been looking at here, is how uniformly the microcapsules are spread across the cloth. And also we wanted to have an idea of their dimensions. And then, after the material’s being used, we wanted to see how the microcapsules react, they are supposed to explode and release the perfume.

And in fact, what we’ve seen here is that they are indeed microcapsules that have exploded and thus released their perfume.

- Spread across – разбросанный.

- Dimension – размер.

- To explode – взрываться.

- To release – выпускать, освобождать.

At the “Institut Francias du Textile et de l’habillement” outside Lyons intelligent textiles are tested for resistance against heat, flames, tearing, liquids. Engineers work on several Europe-wide projects and also invent their own textiles for the future. Once the concept has been established, the cloth is modeled to a chosen design; and added to a virtual collection of tomorrow’s fashion. The dreams to become a reality, you need a plasma machine like this. Here, in a vacuum, textiles are put in contact with different gases: oxygen, nitrogen, fluoride, or ammonia. In this way researcher Jack Makeone changes the textile properties. Fluorides, for example, make normally absorbent cotton impermeable, while nitrogen makes normally resistant materials absorbent. Nitrogen will separate off and try to impregnate itself in the textiles, so using nitrogen gas you can make a kind of water plasma which will attach itself to the surface. And when you put water next to this, there is a very strong affinity and that makes the material that absorbs very easily, which is good for cleaning materials or for absorbing sweat, or for sticky materials or for printable materials. On the other hand, fluoride gas makes cotton water-resistant, so when it rains, it’s impermeable, but still comfortable.

- Resistance against heat, flames, tearing, liquids – устойчивость относительно жары, огня, износа, жидкости.

- Oxygen – кислород.

- Nitrogen – азот.

- Fluoride – фторид.

- Ammonia – аммиак.

- To separate off – отделять.

- To impregnate – насыщать, наполнять.

- Affinity – сходство.

In these workshops a European programme to make threads of the future is being researched. Christophe Angelloz is developing polypropylene thread that resists high temperatures. The polypropylene is mixed with chemical microparticles whose composition is a commercial secret. The mixture is pummelled, melted, stretched and woven into yarn.

It’s all polypropylene, but by changing the manufacturing conditions like the extrusion temperature, the weaving speed, the stretching tension you can optimize the thread production.

Threads with like others made at the centre will now undergo testing to see if they might be useful in the creation of the new intelligent textiles of the future.

- Workshop – цех.

- Polypropylene thread – полипропиленовая нить.

- To pummel – обрабатывать, трамбовать.

- To melt – плавить.

- To stretch – вытягивать.

- Extrusion temperature – температура формования искусственного волокна.

Если вы нашли ошибку, пожалуйста, выделите фрагмент текста и нажмите Ctrl+Enter.